Wholesalers across APAC face constant pressure to manage high order volumes while keeping operations accurate and efficient.

Manual order processing often leads to costly mistakes, delayed shipments, and wasted time that could be spent strengthening customer relationships, making it harder to scale and stay competitive in fast-moving markets.

AI-powered ordering offers a practical solution. By streamlining routine processes and enhancing decision-making, wholesalers can minimize errors, expedite fulfillment, reduce costs, and improve customer satisfaction.

This article examines the implications of AI-powered ordering for wholesale distribution, the benefits it offers, and its comparison with traditional systems. It also covers the leading industries, key success metrics, and best practices for wholesalers in the APAC region.

What Is AI-Powered Ordering in Wholesale?

AI-powered ordering refers to advanced software that uses algorithms, demand forecasting, and process automation to handle customer orders from start to finish.

Instead of relying on manual data entry or basic ERP inputs, this approach validates requests in real time, checks stock availability, and initiates fulfillment automatically. It reduces the chance of human error while ensuring that orders are processed faster and with greater accuracy.

How It Differs from Traditional Ordering

Traditional ordering relies heavily on manual checks. Staff members often need to review requests, confirm available stock, and create the required documentation before fulfillment can begin.

This slows down the process and leaves room for errors such as duplicate entries or overlooked shipments. Automated ordering removes these bottlenecks by validating each request instantly, aligning it with inventory data, and triggering fulfillment with minimal human involvement.

The result is a reliable system that helps wholesalers scale more effectively, including those managing complex food service operations.

Typical Workflow

A simplified process looks like this:

Order request → Validation against stock levels → Automated fulfillment initiation → Real-time tracking and reporting

This workflow also integrates with AI inventory management, ensuring that stock levels are updated continuously and reordering is triggered before shortages occur. The result is a streamlined system that supports accurate, timely, and cost-effective wholesale distribution.

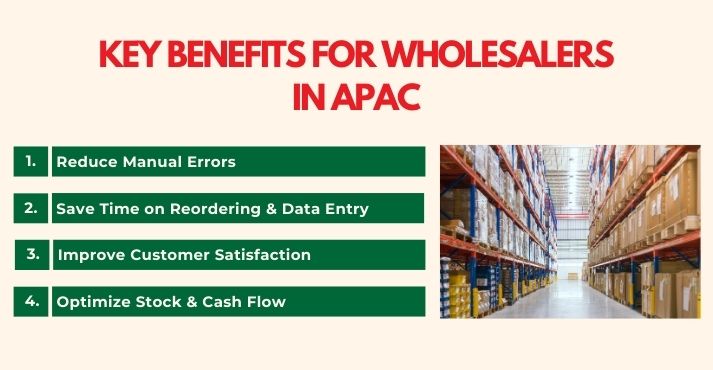

Key Benefits for Wholesalers in APAC

Wholesalers in APAC operate in highly dynamic markets where speed, accuracy, and cost efficiency determine competitiveness.

Automated ordering can streamline these processes, helping businesses handle larger order volumes while minimizing risks. Below are the major benefits:

1. Reduce Manual Errors

Human error in order entry leads to costly mistakes, such as duplicate SKUs, incorrect pricing, or stock mismatches. Automated checks validate SKUs, pricing, and quantities instantly, reducing error rates significantly.

For example, Worldtech Electronics in Thailand scaled from managing 200 SKUs to processing 20,000 monthly e-commerce orders while maintaining 98% delivery accuracy after strengthening its digital order workflows

2. Save Time on Reordering and Data Entry

Reordering based on demand and stock thresholds eliminates hours of repetitive data entry. Teams can redirect that time toward higher-value activities. Nestlé Malaysia’s e-distributor Rurutiki achieved this by centralizing inventory visibility and reducing overselling.

The shift eliminated around 70% of manual processes, freeing staff to focus on better supplier negotiations and customer engagement. This is a strong example of smart wholesale order automation in practice.

3. Improve Customer Satisfaction

Late or inaccurate orders directly affect customer retention, especially in competitive wholesale markets. By tightening fulfillment workflows, wholesalers can ensure consistent service levels across every transaction.

Faster turnaround times and accurate deliveries build trust and reduce the likelihood of disputes, while transparent order tracking strengthens confidence.

For wholesalers in APAC, where customer expectations are influenced by competitive food and beverage markets, maintaining accuracy and reliability can be the deciding factor in long-term relationships.

4. Optimize Stock and Cash Flow

Predictive analytics help wholesalers keep the right balance of inventory, avoiding both over-buying and stock shortages. This is especially important in APAC, where demand often fluctuates during festivals, seasonal export cycles, or sudden market changes.

A recent study published in ScienceDirect found that companies using modern forecasting and order processing methods reduced demand forecasting errors by 10-20%.

For wholesalers, this translates into more accurate purchase planning, better use of warehouse space, and improved cash flow management.

Proactive vs. Reactive Ordering — Why AI Wins

Wholesalers across APAC often struggle with the difference between proactive and reactive order management. Reactive processes rely on human intervention, typically responding only after issues arise, which leads to delays and increased costs.

Proactive systems anticipate demand and ensure stock is managed before disruptions take place. This approach helps businesses handle larger volumes with fewer errors and greater efficiency.

Comparison of Ordering Approaches

| Aspect | AI-Powered Ordering | Manual or Traditional Ordering |

| Accuracy | Automated validation ensures fewer mistakes | Prone to human errors in data entry |

| Speed | Instant reordering and processing | Slower due to manual checks and approvals |

| Forecasting | Predicts demand spikes and seasonal trends | Restocking only after shortages appear |

| Cost | Reduces waste and operational inefficiencies | Higher costs from errors and delays |

Applications by Industry in APAC

Across Asia-Pacific, businesses face rising supply chain costs, shorter product lifecycles, and stricter compliance regulations.

Predictive approaches to ordering and inventory are helping distributors and manufacturers streamline operations while keeping pace with regional demand shifts.

1. Food & Beverage Distribution

Distributors use predictive tools to forecast seasonal demand spikes, such as the increased consumption of beverages during the Lunar New Year in China or Ramadan in Indonesia.

Expiry-date tracking also reduces spoilage, an increasing challenge in the region’s fast-moving foodtech sector.

2. Consumer Goods & Retail

In Southeast Asia’s multi-location retail chains, inventory balancing is critical. Wholesalers use automated reordering to prevent stockouts in urban outlets while avoiding excess storage in smaller towns. This ensures consistency across markets with varied consumer purchasing power.

3. Industrial Supply & Manufacturing

F&B manufacturers and distributors across APAC often operate on just-in-time models. Real-time usage data from sensors can trigger bulk reorders before shortages disrupt production or deliveries.

This helps minimize downtime in food processing plants, bakeries, and distribution centers, ensuring smooth operations and timely fulfillment.

4. Pharmaceuticals & Healthcare

Hospitals and distributors in the APAC region rely on error-free tracking to maintain compliance with government regulations, such as those set by Singapore’s Health Sciences Authority (HSA).

Automated reorder points reduce the risk of shortages in critical medicines, ensuring patients receive timely care.

Top AI Ordering Platforms for Wholesalers

Several platforms offer wholesale distributors the ability to manage high-volume orders more efficiently. While each solution has a different focus, they share the same goal: reducing manual errors, improving demand visibility, and streamlining fulfillment.

| Platform | Key Features | Proactive Benefits | Reactive Coverage |

| Esker | Automated order capture via OCR and ERP integration | Cuts down manual entry and accelerates order processing | Built-in escalation workflows for exceptions |

| Zoho Inventory | Stock level tracking, reorder point automation, and integrations with e-commerce | Helps avoid stockouts by monitoring thresholds in real time | Manual overrides available for urgent adjustments |

| SAP (S/4HANA, SAP Business One) | Enterprise-grade automation, forecasting modules, and supplier collaboration tools | Provides demand predictions and supply chain visibility | Compatible with legacy systems for gradual transitions |

These platforms are commonly adopted across the wholesale and distribution sectors in APAC, offering both proactive control through predictive functions and reactive coverage in the event of unexpected disruptions.

Measuring ROI — Which KPIs Improve With AI Ordering

For wholesalers, efficiency gains are best proven through measurable outcomes. Tracking the right KPIs reveals how order management improvements lead to reduced costs, faster service, and stronger customer loyalty.

Each indicator below reflects direct operational impact:

| KPI | Before AI Ordering | After AI Ordering | % Improvement |

| Order Accuracy % | Frequent errors in SKUs, pricing, or quantities | Automated validation improves wholesale order accuracy | 40–60% fewer errors |

| Fulfillment Time per Order | Manual verification causes delays | Real-time checks and routing shorten processing | 25–35% faster |

| Manual Hours Saved per Week | Teams spend hours on re-entry and approvals | Automation frees staff for higher-value tasks | 8–12 hours saved per team |

| Stock Turnover Rate | Overstocking and shortages reduce efficiency | Predictive AI forecasts improve inventory balance | 15–20% better turnover |

| Customer Satisfaction | Errors and late shipments lower repeat orders | Reliable accuracy and faster service boost retention | NPS gains of 10–15 points |

Focusing on these KPIs allows wholesalers to quantify value beyond cost savings. Improvements in order precision, fulfillment speed, and inventory alignment support long-term competitiveness in sectors where margins are tight and demand is highly seasonal.

Challenges and Considerations for APAC Wholesalers

While automated ordering solutions offer benefits, wholesalers in APAC face adoption hurdles. Integration with older ERP systems often requires customization, which can delay rollouts.

Upfront investment is also a concern for mid-sized distributors who operate on thin margins. Staff training is essential for adapting to new workflows, and resistance to changing long-standing practices can hinder progress.

Region-specific challenges add further complexity. Multiple languages, currencies, and tax structures create obstacles for wholesalers serving several markets. Local regulations regarding data privacy and trade tariffs must be considered.

In rural areas, uneven infrastructure still slows digital adoption, making consistent connectivity a barrier to scaling solutions across diverse markets.

The GSMA reports that 47% of the APAC population lacked mobile internet access in 2023, highlighting how uneven connectivity continues to limit technology adoption in less urbanized areas.

| Pros | Cons |

| Higher order accuracy and faster fulfillment | Upfront software and integration costs |

| Improved forecasting through predictive technology | Training requirements for staff to adjust to new systems |

| Better compliance tracking across regions | Resistance to replacing manual processes |

| Scalability across multiple markets | Connectivity and infrastructure gaps in rural APAC supply chains |

Adoption trends show that interest in advanced supply chain automation across APAC is growing, but success depends on balancing efficiency goals with readiness across compliance, workforce skills, and infrastructure.

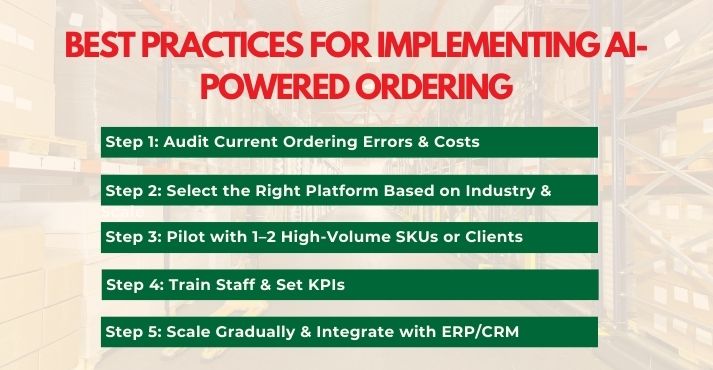

Best Practices for Implementing AI-Powered Ordering

Implementing automated ordering requires a structured approach to avoid costly mistakes and ensure long-term results. Wholesalers can maximize efficiency by following a phased rollout, starting small and expanding once processes prove successful.

Step 1: Audit Current Ordering Errors and Costs

Begin with a review of error rates, order returns, and the staff time spent on manual entry. Quantifying the impact helps build a solid business case for investment and sets a baseline for future measurement.

Step 2: Select the Right Platform Based on Industry and Scale

Not every system fits all sectors. Food and beverage distributors, for example, require expiry tracking and compliance checks, while industrial suppliers may prioritize bulk reordering tools. Choosing a platform aligned to operational needs ensures better results.

Step 3: Pilot with 1–2 High-Volume SKUs or Clients

Starting with a narrow focus reduces risk and provides measurable outcomes. For instance, piloting predictive ordering in APAC wholesale markets often yields immediate benefits, including reduced stockouts during peak demand periods.

Step 4: Train Staff and Set KPIs

Successful implementation depends on staff readiness. Training ensures teams understand how to monitor order accuracy, fulfillment speed, and stock turnover. Well-defined KPIs provide a way to measure progress against the initial audit.

Step 5: Scale Gradually and Integrate with ERP/CRM

Once results are proven, expand across more SKUs, clients, or regions. Full integration with ERP and CRM systems creates a single source of truth for orders, inventory, and customer data, reducing duplication of effort.

For wholesalers connected to hospitality supply chains, these practices also point toward the future of dining, where reliable ordering systems reduce waste, ensure timely deliveries, and support menu flexibility during high-demand seasons.

Frequently Asked Questions

What is AI-powered ordering in wholesale?

It’s a system that automates purchase and replenishment decisions using data from sales, stock levels, and demand trends. This helps wholesalers streamline operations and minimize manual effort.

How does AI reduce errors in wholesale ordering?

By analyzing order patterns and inventory in real time, it flags discrepancies and prevents duplicate or incorrect entries. This improves wholesale order accuracy and lowers costly returns.

Which industries in APAC benefit most from AI ordering?

Food & beverage distribution, consumer goods, manufacturing, and healthcare are the sectors that see the most substantial impact. These sectors often handle high volumes, perishable items, or stringent compliance requirements.

What are the best AI ordering platforms for wholesalers?

Platforms like Esker, Zoho Inventory, and SAP stand out for their features, including automated order capture, predictive stock management, and enterprise-grade forecasting. The right choice depends on scale and industry.

Can AI ordering integrate with ERP/CRM systems?

Yes, most platforms offer seamless integration with ERP and CRM tools. This ensures inventory, sales, and customer data are connected, reducing duplication and improving efficiency.

What KPIs show the ROI of AI ordering?

Key metrics include order accuracy %, fulfillment time per order, manual hours saved, stock turnover rate, and customer satisfaction. Predictive AI typically improves all five over time.

Conclusion

Automated ordering systems help wholesalers save time, reduce errors, and improve operational efficiency. By validating orders, predicting demand, and streamlining fulfillment, these solutions ensure accurate stock management and higher customer satisfaction.

Food and beverage distributors benefit most, particularly when handling seasonal demand or strict compliance requirements.

Tracking metrics such as order accuracy, fulfillment speed, manual hours saved, and stock turnover shows the impact on operational improvements.

Following best practices, such as auditing processes, piloting high-volume SKUs, training staff, and scaling gradually, ensures a smooth implementation.

For wholesalers looking to stay competitive in fast-moving markets, investing in smart, automated ordering workflows is becoming essential.