Many strong consumer brands encounter a challenge when preparing for retail rollouts: scaling production without losing product quality or traceability.

Meeting retailer expectations requires consistency across every unit, and even small mistakes in packaging or compliance can result in costly setbacks.

This is why working with co-packers has become essential for consumer packaged goods and food and beverage businesses aiming to grow.

Co-packers, or contract manufacturers, provide the facilities, expertise, and capacity needed to move from limited production runs to large-scale distribution.

They allow brands to focus on innovation and market expansion while ensuring products are packaged efficiently and in line with retail standards.

This article will outline how to identify the right co-packing partners, establish reliable systems for quality assurance and traceability, minimize common risks, and meet retail compliance requirements for smooth and successful rollouts.

What is a Co-Packer (and When to Use One)?

A co-packer is a partner that takes on the operational side of production, allowing brands to focus on growth while outsourcing tasks such as filling, labeling, packaging, and shipping.

The product owner provides specifications, which the co-packer turns into standard operating procedures that guide each production run.

After quality checks, finished goods are released to retail distribution centers, creating a clear flow: brand specifications, co-packer procedures, production, quality assurance, and delivery.

Working with co-packing services delivers important advantages for businesses preparing for retail rollouts. It allows faster scaling without heavy capital investment, provides access to certifications and equipment required by retailers, and extends geographic reach through established facilities.

According to Fortune Business Insights, the global contract packaging market is projected to grow from $98.77 billion in 2025 to $141.14 billion by 2032, at a compound annual growth rate (CAGR) of 5.23%.

For many manufacturers, this partnership proves valuable during demand spikes, multi-SKU expansions, seasonal surges, and private label launches, where speed and consistency are critical to meeting retailer expectations while maintaining product quality.

In-House vs. Co-Packing

When brands weigh whether to keep production internal or outsource to co-packers, it comes down to balancing control with scalability.

In-house operations are often ideal for early-stage batches, pilot projects, or highly bespoke items where oversight and small-batch flexibility matter most.

However, as retail orders increase, shifting to co-packers can deliver scale, efficiency, and compliance advantages that are difficult to achieve internally.

Many contract packaging companies bring established systems, certifications, and equipment that reduce the burden of building these capabilities from scratch.

Below is a comparison of in-house vs. co-packing approaches:

| Factor | In-House | Co-Packing |

| CapEx/OpEx | High upfront CapEx, lower OpEx | Lower CapEx, predictable OpEx |

| Speed to Scale | Slower due to equipment limits | Faster with existing capacity |

| Quality Systems Maturity | Dependent on internal resources | Mature, proven systems |

| Certifications | Costly and time-consuming to obtain | Often already in place |

| Unit Economics at Volume | Less efficient at higher volumes | More favorable at scale |

| Retailer Onboarding Time | Longer, internal learning curve | Faster due to experience |

| Traceability Depth | Limited unless heavily invested | Robust systems for compliance |

| Risk Concentration | Higher, as all risk stays internal | Shared across multiple clients |

| Flexibility for Short Runs | High for pilots and testing | Less flexible, optimized for scale |

For early pilots or specialty food processing, in-house production offers control and agility. Once demand grows, outsourcing larger runs to co-packers allows brands to meet retailer expectations, optimize costs, and ensure quality systems remain consistent at scale.

Overcoming the Big Barriers

Even strong brands can face hurdles when working with a food co-packer partnership. Common blockers include minimum order quantities that restrict smaller runs, limited access to line time during peak seasons, lead-time volatility, and issues with artwork or labels that slow approvals.

Other challenges, such as adapting to change management, meeting strict retailer routing requirements, and coordinating freight, can quickly impact launch timelines if not managed correctly.

The best way to overcome these barriers is to build discipline into planning and communication. Early forecast sharing provides co-packers with visibility into demand, while frozen specifications and packaging timelines minimize back-and-forth communication.

Pre-booked runs and second-source planning create backup options if line time shifts. Scorecards help track performance across quality, delivery, and compliance.

Clear directives keep execution on track, such as:

- Lock die-lines at least four weeks before production.

- Run pre-production approval (PPA) ahead of the first full run.

- Stage freight and ASN testing two weeks before the first shipment.

Disruptions are also a significant factor in co-packing operations. A McKinsey survey found that more than 90% of supply chain leaders reported experiencing at least one major disruption in the past year, and nearly half stated that these disruptions had a material impact on their production plans.

This shows why proactive planning and structured processes are essential for managing food packaging and maintaining smooth operations with co-packing partners.

By following these steps, brands can maintain efficient production while ensuring their products meet retailer expectations.

Quality Systems Brands Need from the Start

When working with a co-packer, it’s essential to understand the quality systems they use and what you are responsible for. For food brands, this includes HACCP and FSMA compliance, while non-food CPG products may require GMP or ISO standards.

The co-packer should provide documentation, including standard operating procedures, critical control point (CCP) records, calibration logs, certificates of analysis, and micro- or environmental test results, where applicable.

Brands are responsible for providing the master formula or bill of materials, detailed packaging specifications, and a change-control process.

They should also retain samples and manage deviation and corrective action workflows to maintain consistency and compliance across all production runs.

A mini checklist for quality oversight includes:

- Allergen controls for food products.

- Foreign-material prevention.

- Line clearance before production.

- Label verification.

- Shelf-life and stability plan.

These systems ensure that products meet regulatory requirements and retailer expectations from the very first production run.

Building Traceability That Retailers Trust

Effective traceability is crucial for CPG brands, ensuring that every product can be tracked from production to shelf.

Under a co-packer agreement, it is important to record key data points for each batch, including lot or batch numbers, ingredients, packaging components, line and production time, operator details, quality control results, pallet identifiers, SSCC codes, and shipment advance ship notices (ASN).

This complete record helps brands respond efficiently to audits, verify compliance, and manage recalls when needed.

Standards such as GS1 barcodes (GTIN, lot, and expiration codes), EPCIS event reporting, and ASN documentation provide a structured way to share traceability information with retailers.

Packaging features, such as QR codes, serialization, tamper-evident seals, and anti-counterfeit elements, further enhance safety, consumer confidence, and recall readiness.

Effective traceability also supports food distribution by allowing quick backward and forward tracking of products across the supply chain.

A 2025 GS1 US survey found that 43% of supply chain leaders reported difficulty maintaining full visibility across operations.

This shows why using detailed traceability data and following established standards is critical for brands to track products, respond to audits, and handle recalls efficiently.

Digital Traceability Stack (Simple, Actionable)

A digital traceability stack allows brands to monitor production and logistics efficiently across multiple systems. Co-packer MES, LIMS, and ERP systems provide operational data, while label and code systems track units and batches.

Warehouse management (WMS) and transportation management (TMS) systems manage storage and shipment, and retail EDI enables seamless communication with retailers.

A centralized portal or view across these systems helps maintain visibility without overcomplicating operations.

Companies with full automation in their supply chains are 61% more likely to manage agility very well compared to those with partial or no automation.

Integrating digital systems in this way supports consistent production, accurate shipments, and quality management across co-packer operations.

When negotiating contracts with co-packers, it is essential to define data ownership and retention, reporting frequency via API or flat file, event granularity, uptime SLAs, and audit access.

Implementing these requirements supports food safety and ensures that F&B co-packing solutions provide reliable, traceable operations across the supply chain.

Co-Packer Selection & Vetting (Step-by-Step)

Selecting the right co-packer is critical for brands preparing for retail rollouts. Start by shortlisting partners based on capability match, including types of fillings, packaging formats, and certifications.

Consider geographic proximity to distribution centers, minimum and maximum production volumes, and surge capacity to handle seasonal or unexpected demand.

The RFI or RFP process should include detailed SKUs and specifications, weekly forecasts, QA requirements, desired traceability levels, sample or scale plans, and pricing models, whether toll or turnkey. Terms covering yield loss, scrap, rework, and storage should also be clearly stated.

Site audits provide insights into operational practices. Assess line layout, sanitation, material flow, QA lab setup, holds and quarantine procedures, rework policies, and training records.

Commercial guardrails help protect your brand and should include IP protection, NDAs, mold or tooling ownership, change-order rules, and service credits for missed expectations.

Following this structured approach is essential for brands learning how to choose a co-packer that aligns with quality, compliance, and growth objectives.

Contracts That Protect Quality & Delivery

Strong contracts are essential to safeguard product quality and ensure timely delivery when working with co-packers.

Start by defining the statement of work (SOW) and service-level agreements (SLA), including metrics such as on-time-in-full (OTIF) delivery, first-pass yield, defect PPM, complaint turnaround time, and CAPA response times.

Clearly specify ownership of product specifications, change control procedures, label approval workflows, artwork freeze dates, and sample sign-offs to ensure consistency across production runs.

Include provisions for business continuity, such as safety stock requirements, dual-site production capability, and disaster response plans.

Price adjustment clauses covering materials or energy costs, along with a regular review cadence, help prevent disputes and ensure financial predictability.

Implementing these contractual measures also supports food security by reducing the risk of supply chain disruptions and protecting the trust of both consumers and retailers.

Private Label & White-Label Plays

Private label and white-label co-packing solutions are effective for brands looking to expand into retailer exclusives, create channel-specific packs, or launch seasonal collaborations.

Using co-packer capabilities, brands can bring these products to market quickly without investing in additional equipment or production capacity, while meeting retailer requirements for packaging, labeling, and quality.

To manage these programs successfully, it is important to establish guardrails around brand standards, differentiated specifications, and margin modeling.

Forecasts should be carefully aligned with retailer demand, and potential markdown risks should be considered to protect profitability.

Proper planning and clear guidelines ensure that private label initiatives deliver value without compromising overall brand integrity or operational efficiency.

Launch & Scale Playbook (Week-by-Week)

A structured, week-by-week approach ensures that retail rollouts stay on schedule and maintain quality standards.

From T-8 to T-6 weeks, brands should conduct a pilot production run, test packaging lines, validate quality control methods, and perform transport trials to identify potential issues before full-scale production. These early checks help prevent delays and reduce risks during launch.

Between T-5 and T-3 weeks, artwork should be finalized, ASN and EDI systems tested, retailer items set up, and distribution center appointment windows confirmed.

In the final two weeks leading up to launch, the first full production run occurs, with heightened QC sampling, retained sample libraries, and close monitoring of the first shipments.

Post-launch, weekly war-room meetings track fill rates, customer complaints, defect rates, and returns, enabling continuous improvement and ensuring smooth scaling for future rollouts.

Risk Register & Mitigations

Identifying and addressing potential risks early ensures that retail rollouts run smoothly without compromising quality or delivery. A structured risk register with clear mitigation strategies helps brands and co-packers stay aligned and proactive.

- Labeling Errors and UPC Mismatches: A 4-eyes artwork review and barcode verification process helps prevent mistakes that could result in retailer rejections or shipment delays. Maintaining strict checks ensures all labels and UPCs meet specifications.

- Yield Variance: Mass-balance checks and adherence to BOM tolerances keep production predictable and minimize waste. Early detection of deviations allows corrective actions before issues escalate.

- Food Allergens and Cross-Contact: Strict line clearance procedures, validated sanitation protocols, and detailed allergen maps protect consumers and ensure regulatory compliance, thereby reducing the risk of contamination.

- Traceability Gaps: Mandatory scan events, lot tracking at each production stage, and exception reporting maintain end-to-end visibility across the supply chain, supporting audits and rapid issue resolution.

- Capacity Challenges: Alternate production windows, pre-booked overtime, and onboarding of second-source co-packers prevent supply interruptions and ensure timely delivery during demand surges.

Economics & ROI (How to Make the Math Work)

Evaluating co-packing partnerships requires more than comparing fees. Brands need a clear view of total costs, ROI levers, and simple ways to quantify financial impact.

Insights gathered from industry events, such as a trade show for sustainable food options, can help brands benchmark costs and identify efficient co-packing practices.

Cost Model

Understanding the cost structure is essential to evaluate co-packer options. Toll fees and turnkey arrangements that include materials and conversion form the baseline.

Brands should also account for minimum order quantities and line-time charges, packaging allowances, and freight terms such as FOB or delivered to forecast production costs accurately.

ROI Levers

Several factors can significantly influence the financial benefits of co-packing. Speed-to-shelf, fewer chargebacks, lower scrap and rework, right-sized inventory, and minimized outages all contribute to a better return on investment.

Monitoring these factors allows brands to quantify operational efficiency in practical terms.

Quick ROI Calculation

To estimate ROI, use a straightforward formula:

- (GM uplift from on-time retail + avoided penalties) − (conversion + materials deltas + logistics)

This approach allows brands to see the financial impact of co-packing decisions in a simple, actionable way.

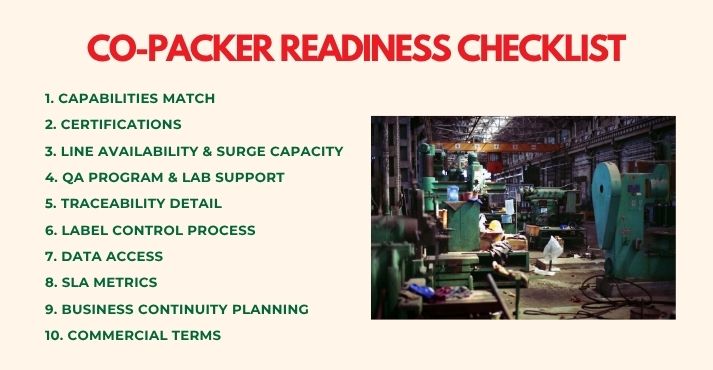

Co-Packer Readiness Checklist

- Capabilities Match: Ensure the co-packer can handle your required filling and packaging formats to meet product specifications and retailer expectations.

- Certifications: Verify relevant certifications, such as GFSI, HACCP, or FSMA for food, and GMP or ISO for non-food CPG, to ensure compliance and quality standards.

- Line Availability and Surge Capacity: Confirm production line availability and the ability to handle seasonal peaks or sudden demand spikes without delays.

- QA Program and Lab Support: Assess the co-packer’s quality assurance processes, lab capabilities, and sample retention policies to maintain product integrity.

- Traceability Detail: Check lot, case, and pallet-level traceability, and confirm EPCIS/ASN integration for seamless supply chain tracking.

- Label Control Process: Review artwork approval workflows, barcode verification, and change management procedures to prevent labeling errors.

- Data Access: Ensure you have access to operational and production data via APIs or portals, and clarify data ownership and retention policies.

- SLA Metrics: Confirm service-level agreements, including key performance metrics, chargebacks, and service credits for missed expectations.

- Business Continuity Planning: Evaluate safety stock levels, dual-site production capability, and lead time planning to reduce risk of supply disruptions.

- Commercial Terms: Review pricing models, minimum order quantities, and payment terms to align financial and operational expectations.

FAQs

What is a co-packer and how do they work with brands?

A co-packer manufactures, fills, labels, and packages products according to the brand’s specifications. Brands provide formulas, packaging requirements, and forecasts, while the co-packer handles production and logistics.

How do co-packers maintain product quality at scale?

Co-packers follow strict SOPs, conduct in-line quality checks, and maintain labs for testing. Retained samples, calibration logs, and validated processes ensure consistent output across large production runs.

What systems track traceability in retail supply chains (barcodes, EPCIS, ASNs)?

Traceability is managed using lot-level barcodes, GS1 standards, EPCIS events, and advance shipping notices (ASNs). These systems provide visibility from production to retailer distribution centers.

What are the risks of using co-packers — and how do we avoid them?

Risks include labeling errors, yield variance, allergen cross-contact, traceability gaps, and capacity constraints. Mitigation strategies involve strict QC, line clearance, scan events, and alternate production planning.

Which co-packers specialize in retail-ready packaging?

Look for co-packers with experience in retail shelf-ready formats, certified packaging capabilities, and knowledge of retailer compliance standards. They should provide packaging trials and line testing before launch.

In-house production vs. co-packing — what’s better for a fast retail rollout?

In-house production is suitable for pilot runs, bespoke products, or small volumes. Co-packing is preferred for scale, automation, and rapid multi-SKU rollouts without large capital expenditure.

How do we meet retailer compliance requirements quickly?

Early planning, frozen specifications, pre-approved artwork, ASN/EDI testing, and clear SOPs help meet retailer compliance. Co-packers with established retail experience can shorten onboarding time.

How do contracts/SOWs prevent delays and chargebacks?

Contracts and statements of work outline timelines, specifications, SLAs, change controls, and penalties. Clear agreements help protect brand interests and reduce risks of missed shipments or quality issues.

Conclusion

Selecting the right co-packing partner ensures a smooth retail rollout. Brands that choose partners with the right capabilities, certifications, and production capacity can scale efficiently without compromising product quality.

Quality assurance programs and lot-level traceability ensure products meet specifications and retailer requirements, reducing errors and compliance risks.

Clear contracts and statements of work set expectations for timelines, responsibilities, and service levels. Well-defined agreements help prevent chargebacks, delays, and disputes, keeping both brand and co-packer accountable.

By combining the right partner, enforceable QA and traceability, and strong contracts, brands can scale faster, maintain quality, and reduce operational risk in retail rollouts.